Carbonyl iron powders (CIP)

Micropowder™ Iron

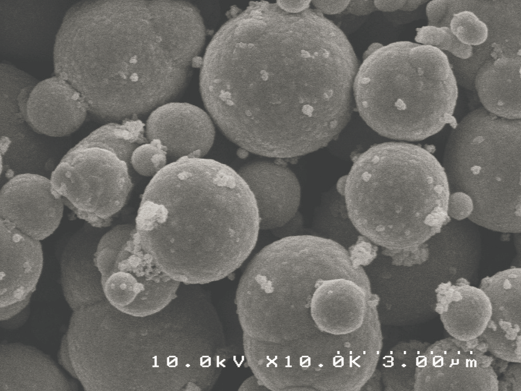

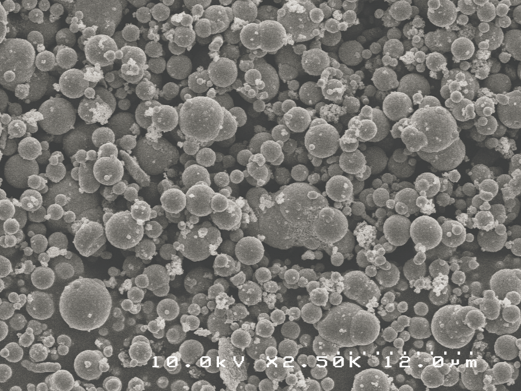

Carbonyl iron powder is manufactured by the chemical decomposition of iron pentacarbonyl. The resulting iron particles are uniform gray microscopic spheres and are ultra pure elemental iron with only traces of carbon, oxygen and nitrogen. Over 25 different grades of iron powder are manufactured through this process and marketed under the trade name Micropowder.

Specific applications include:

- Radar absorbing materials (RAM).

- Precision electronic cores.

- Electromagnetic interference shielding products (EMI/RF).

- Metal injection molding (MIM).

- High-performance powder metallurgy products.

- Magnetic fluids.

- Pharmaceutical supplement.

Physical Properties

The fine size and high purity of the carbonyl iron powders are the principal reasons for their superior properties compared to other forms of iron powders.

Distinct characteristics of the Micropowder™ Iron products include:

- Very fine spherical size.

- Submicron to 10 micron particle diameter.

- High purity with up to 99.5% iron content.

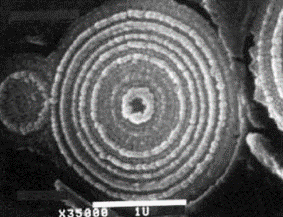

- Unique onionskin structure with cubic crystalline lattice.

- Superior electromagnetic properties.

- Uniform particle size distribution.

Chemistry

In terms of fundamental properties, there are two product families, the “S” grades and “R” grades. The S grades are standard iron grades with a purity level of approximately 97.5%. The impurity is comprised of carbon, oxygen and nitrogen and is the cause of the iron particle’s unique onionskin structure.

R grades are higher purity iron grades with an average purity of 99.5%. Through a hydrogen reduction process, most of the residual carbon and nitrogen have been removed from the iron particle, producing a higher purity iron grade that is lower in durometer hardness and lacking the unique onionskin structure.

Physical Properties

The fine size and high purity of the carbonyl iron powders are the principal reasons for their superior properties compared to other forms of iron powders.

Distinct characteristics of the Micropowder™ Iron products include:

- Very fine spherical size.

- Submicron to 10 micron particle diameter.

- High purity with up to 99.5% iron content.

- Unique onionskin structure with cubic crystalline lattice.

- Superior electromagnetic properties.

- Uniform particle size distribution.

Chemistry

In terms of fundamental properties, there are two product families, the “S” grades and “R” grades. The S grades are standard iron grades with a purity level of approximately 97.5%. The impurity is comprised of carbon, oxygen and nitrogen and is the cause of the iron particle’s unique onionskin structure.

R grades are higher purity iron grades with an average purity of 99.5%. Through a hydrogen reduction process, most of the residual carbon and nitrogen have been removed from the iron particle, producing a higher purity iron grade that is lower in durometer hardness and lacking the unique onionskin structure.

Carbonyl Iron Grades

Specialty Chemicals Performance Reference Guide

| PROPERTIES | APPLICATIONS |

|---|

| Carbonyl Iron Grades | Average Diameter (Microns) | % Iron | Additive | Powder Metallurgy | Electronics | Aerospace & Defense |

|---|---|---|---|---|---|---|

| S-1000 | 7-9 | >97 | No Silica | X | ||

| S-1100 | 4-6 | >97 | No Silica | X | ||

| S-1281 | 4-6 | >97 | Silica | |||

| S-1640 | 3-5 | >97 | No Silica | X | ||

| S-1641 | 3-5 | >97 | Silica | X | ||

| S-1651 | 3-5 | >97 | Silica | X | ||

| S-2101 | 2-4 | >97 | Silica | X | ||

| S-2701 | 2-4 | >97 | Silica | X | ||

| S-3000 | 1-3 | >98 | No Silica | X | ||

| S-3001 | 1-3 | >97 | Silica | X | ||

| S-3700 | 1-3 | >97 | No Silica | X | ||

| S-5000 | 6-7 | >97 | No Silica | X | ||

| S-5641 | 3.4-5.0 | >97 | Silica | X | ||

| R-1470 | 5-8 | >99.5 | No Silica | X | ||

| R-1480 | 7-9 | >99.5 | No Silica | X | ||

| R-1511 | 4-6 | >98.5 | Silica | X | ||

| R-1521 | 4-6 | >98.5 | Silica | X | ||

| R-2410 | 4-7 | >99.5 | No Silica | X | ||

| R-2430 | 4-6 | >99.5 | No Silica | X | ||

| MLE-E | 3.3-5.7 | >97 | Silica | X |